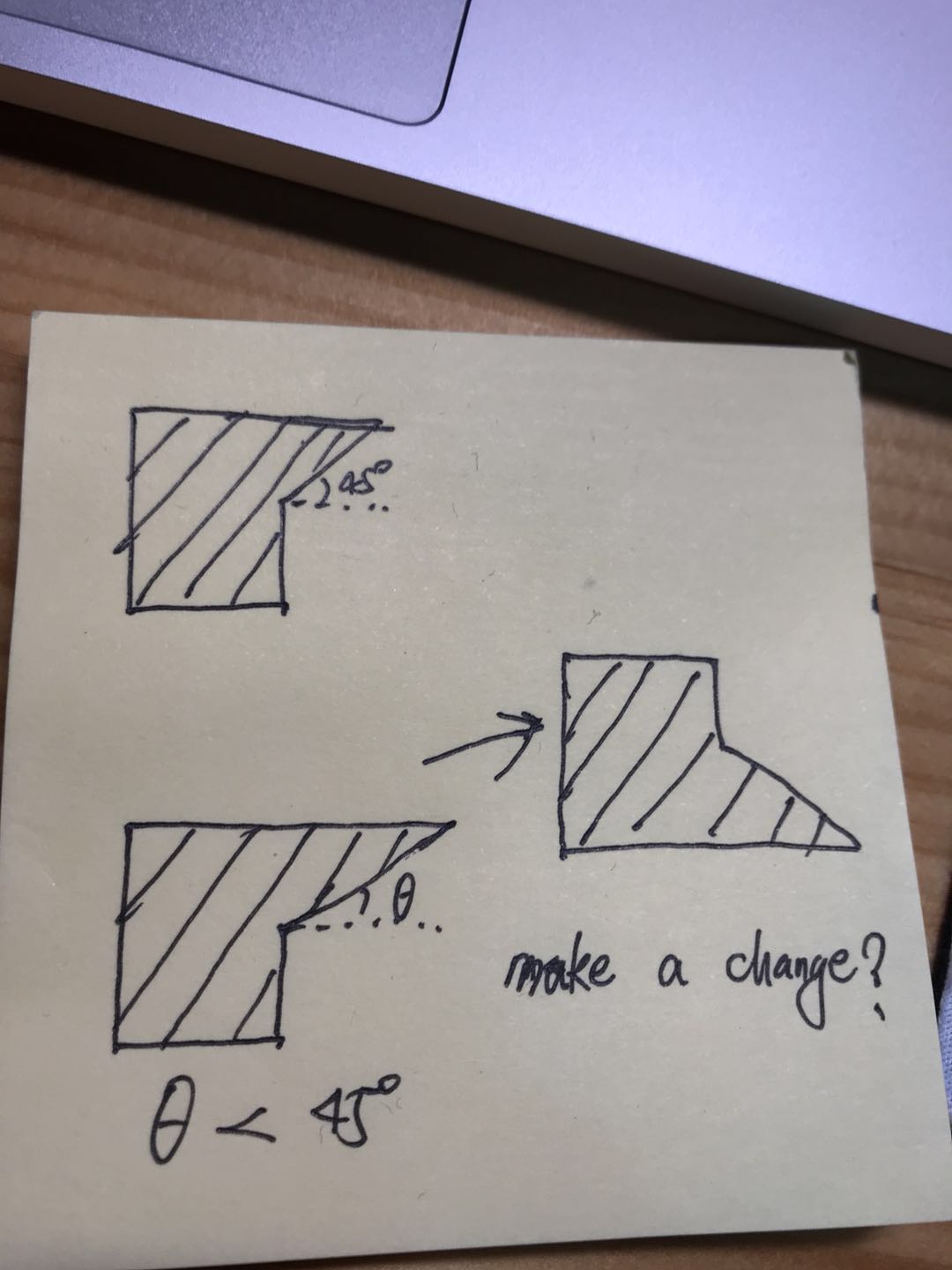

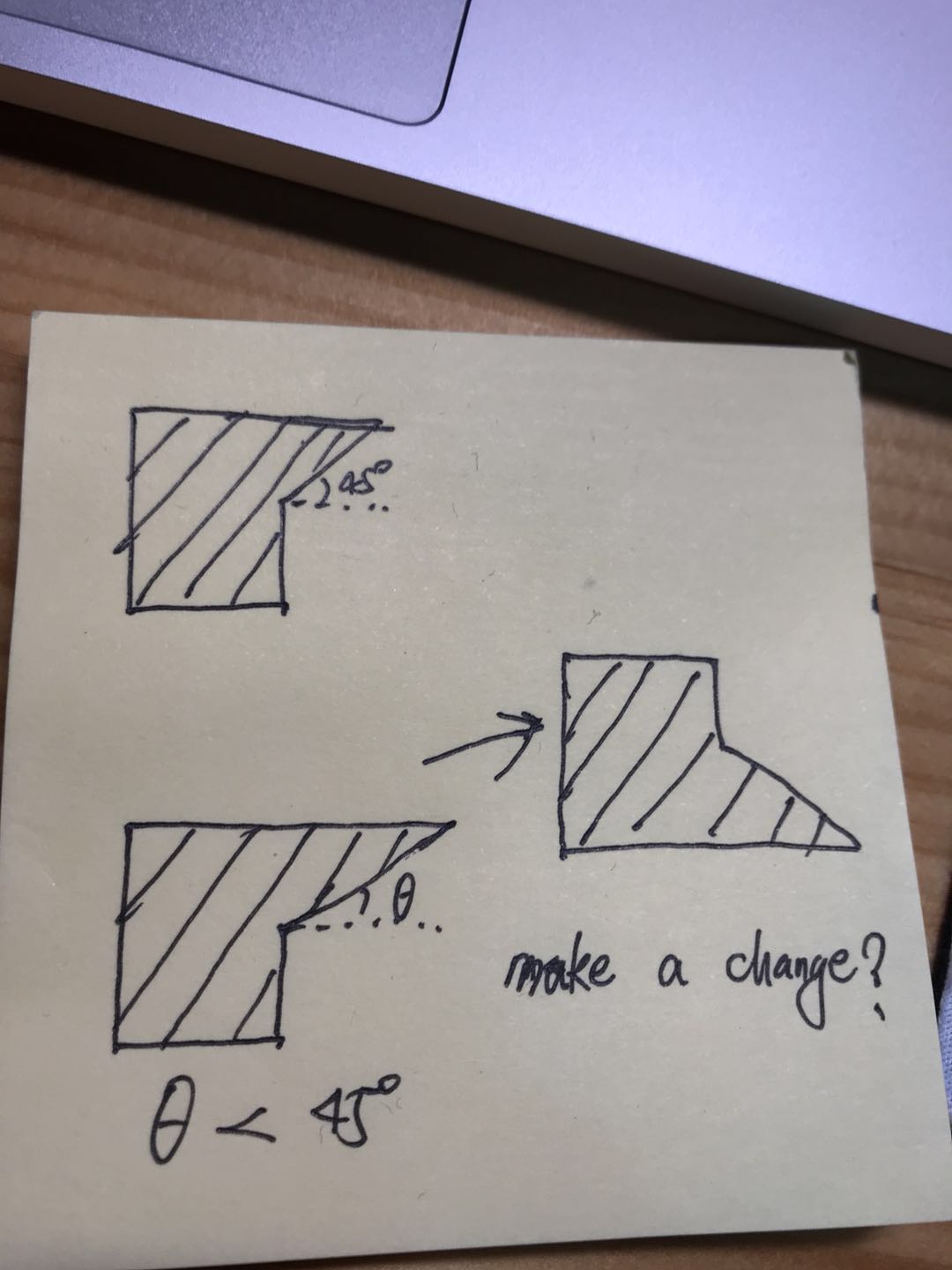

1.The overhang angle of xyz printer is limited to 45 degree and we are unable to print models in the picture below.Hower,we can find another way to print it out, such as using supporting tubes and printing models from up to bottom which is a clear idea raised by a senior.In short, the printer cannot print someting in the air and we're suggested to find a creative and approprate way to print our models effectively.

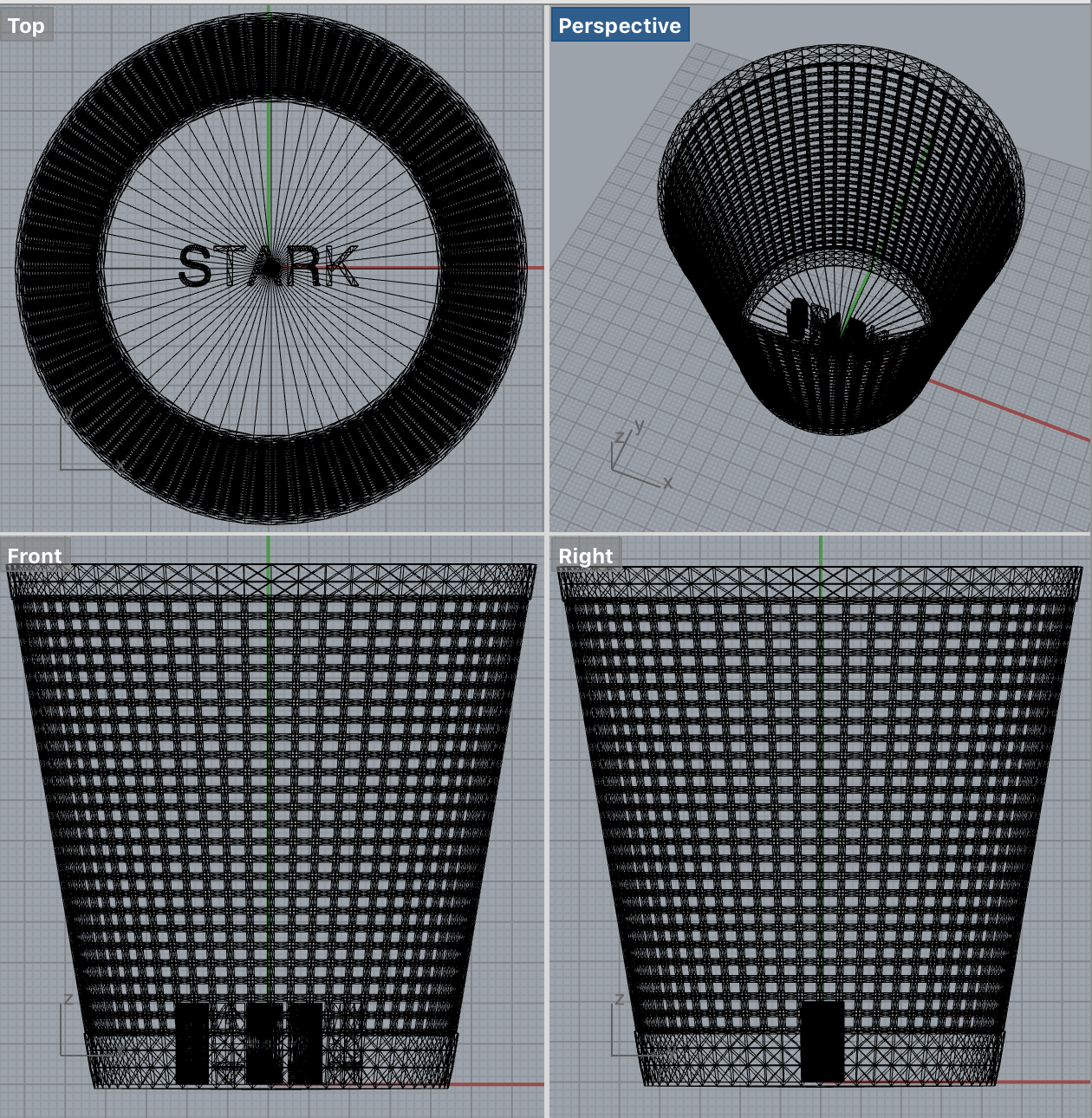

2.Rhino is an excellent software for us to design 3D or 2D models,but we can't ignore the gravity of the meterial especially when it comes out from the nozzle.So we need to trim our models according to our exprience of printing.(pay attention to bridge distance)

bt

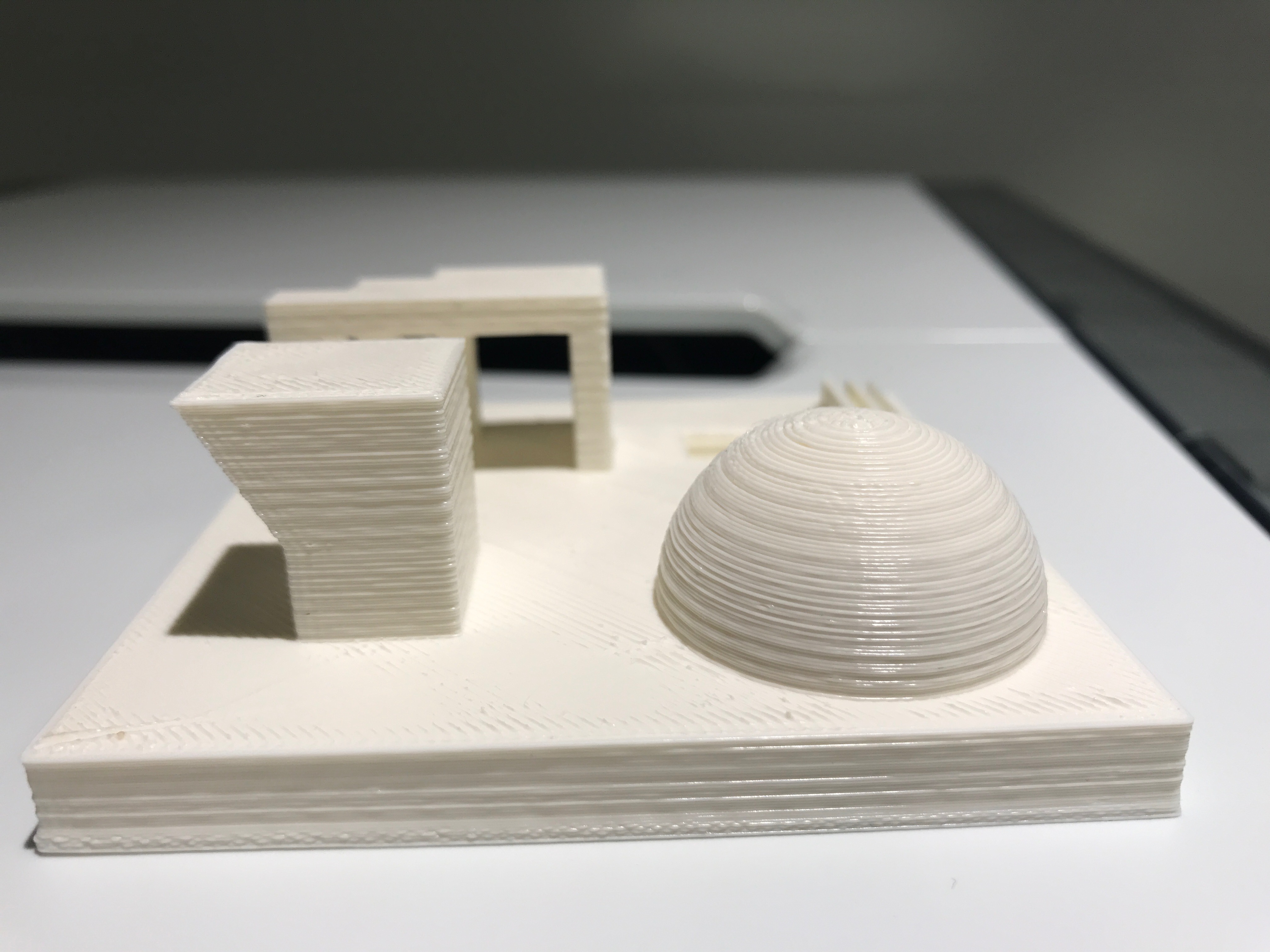

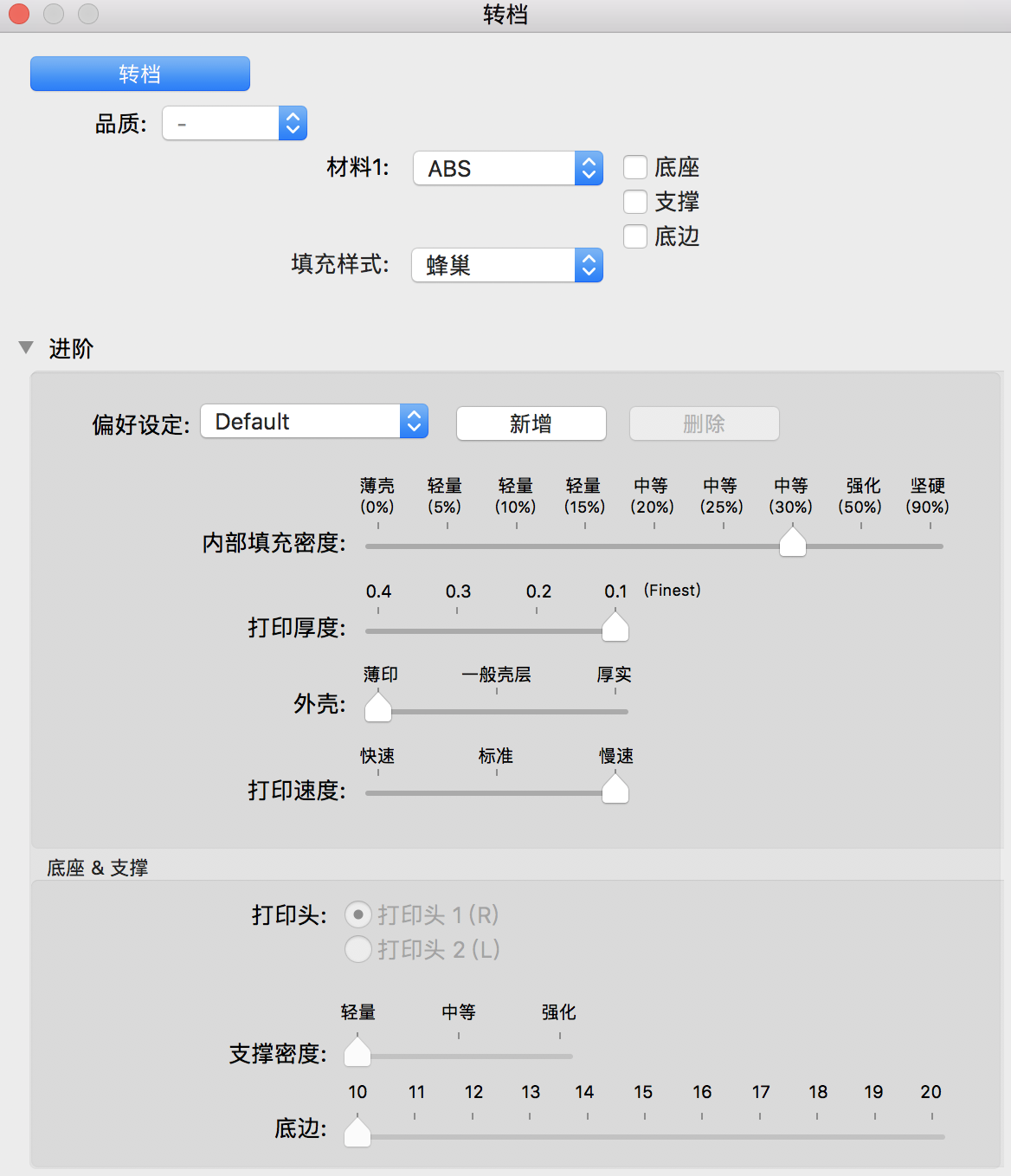

3.Keep a balance between printing time and accuracy.We're suggested to print a hollow model (choosing a 10% infill if it is not possible to make it hollow)or not very tall.

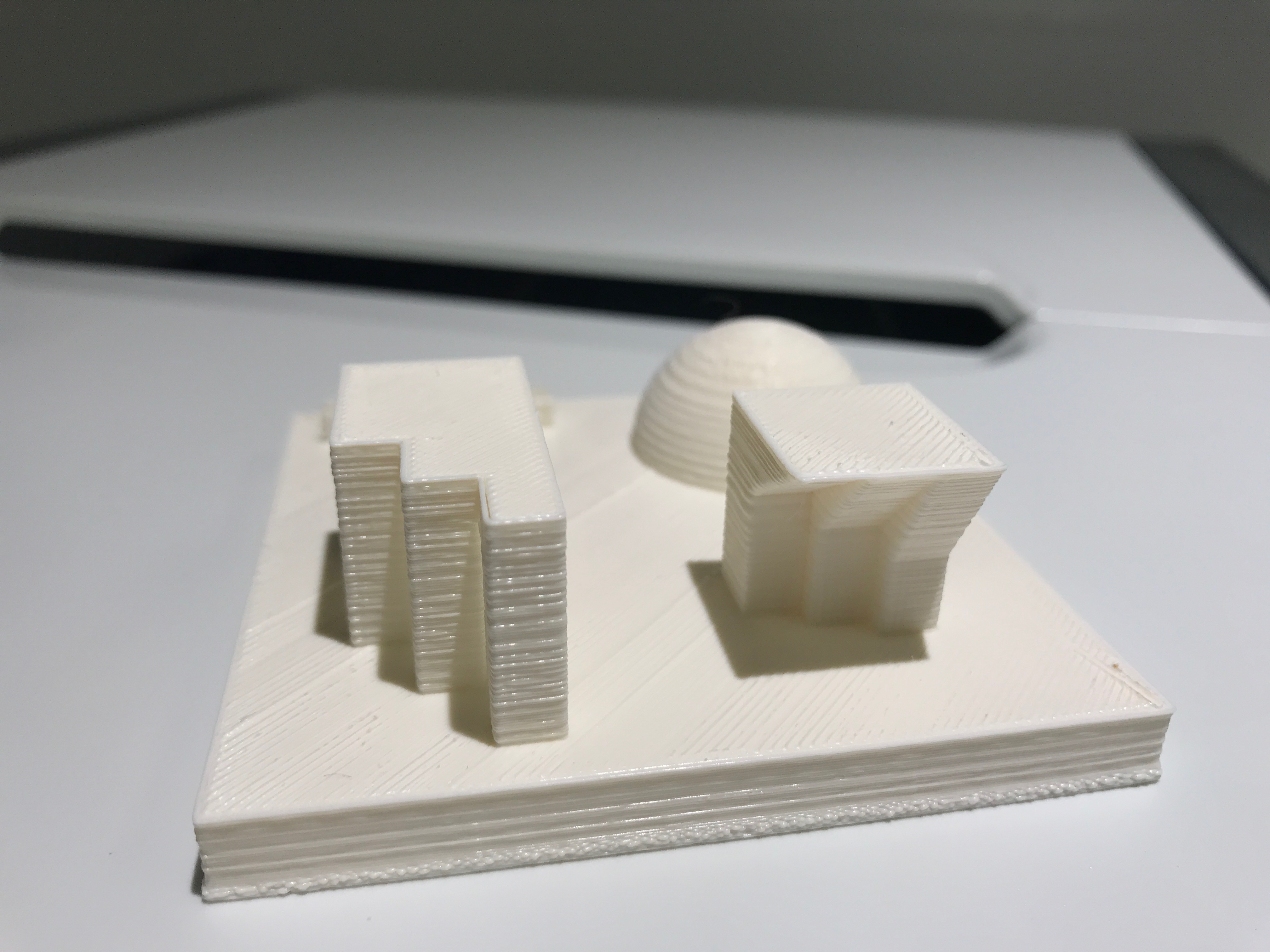

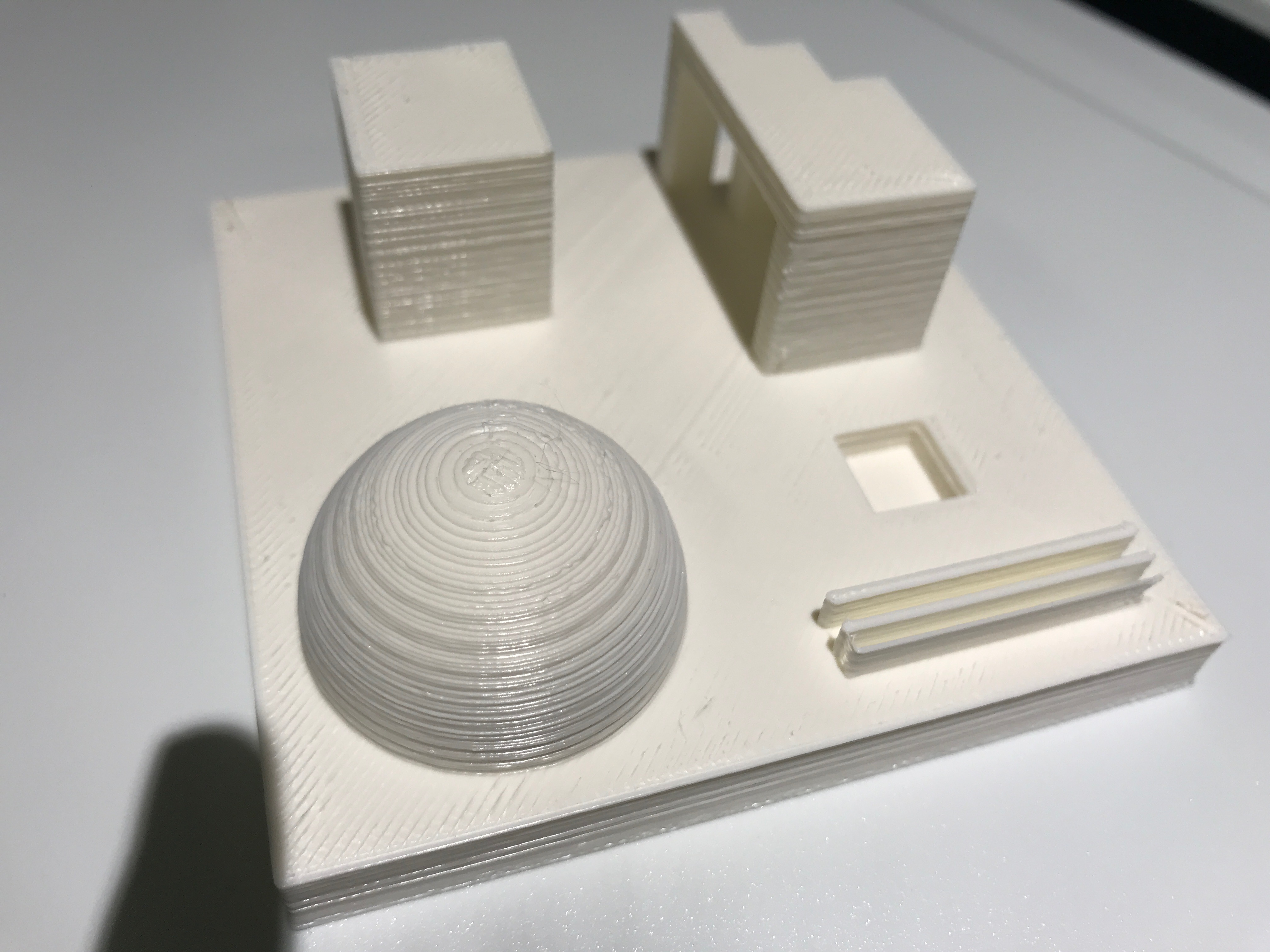

let's take a look from the front,the polgyon layers are distinct and break the beaty of the model.In a gesture to save printing time, Saverio turned down the accuracy of the model.As a teaching model,i think,it has a too thick foundation which wasted some time.

From the back perspective, we can see the differences between differnt slope angles.

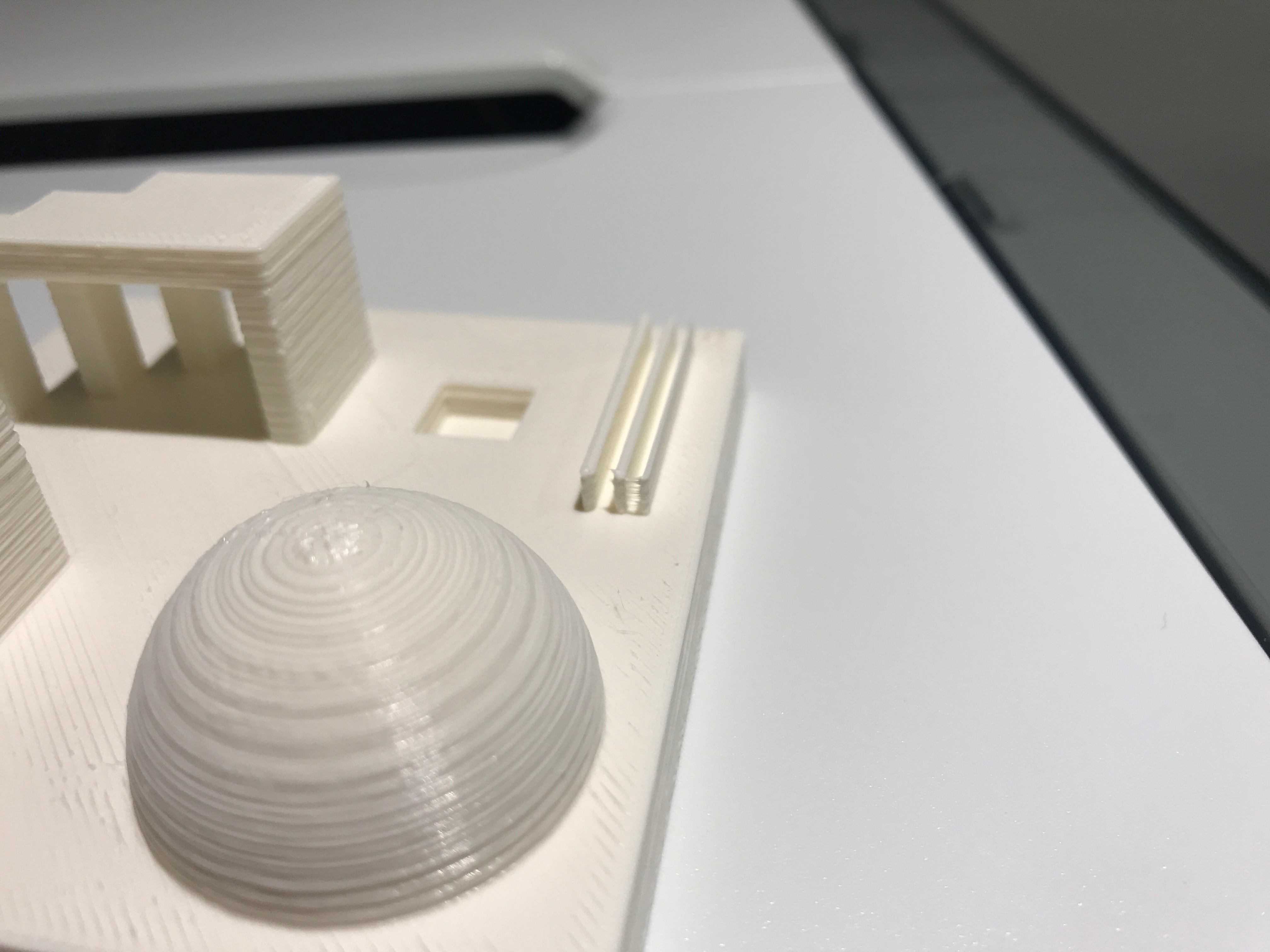

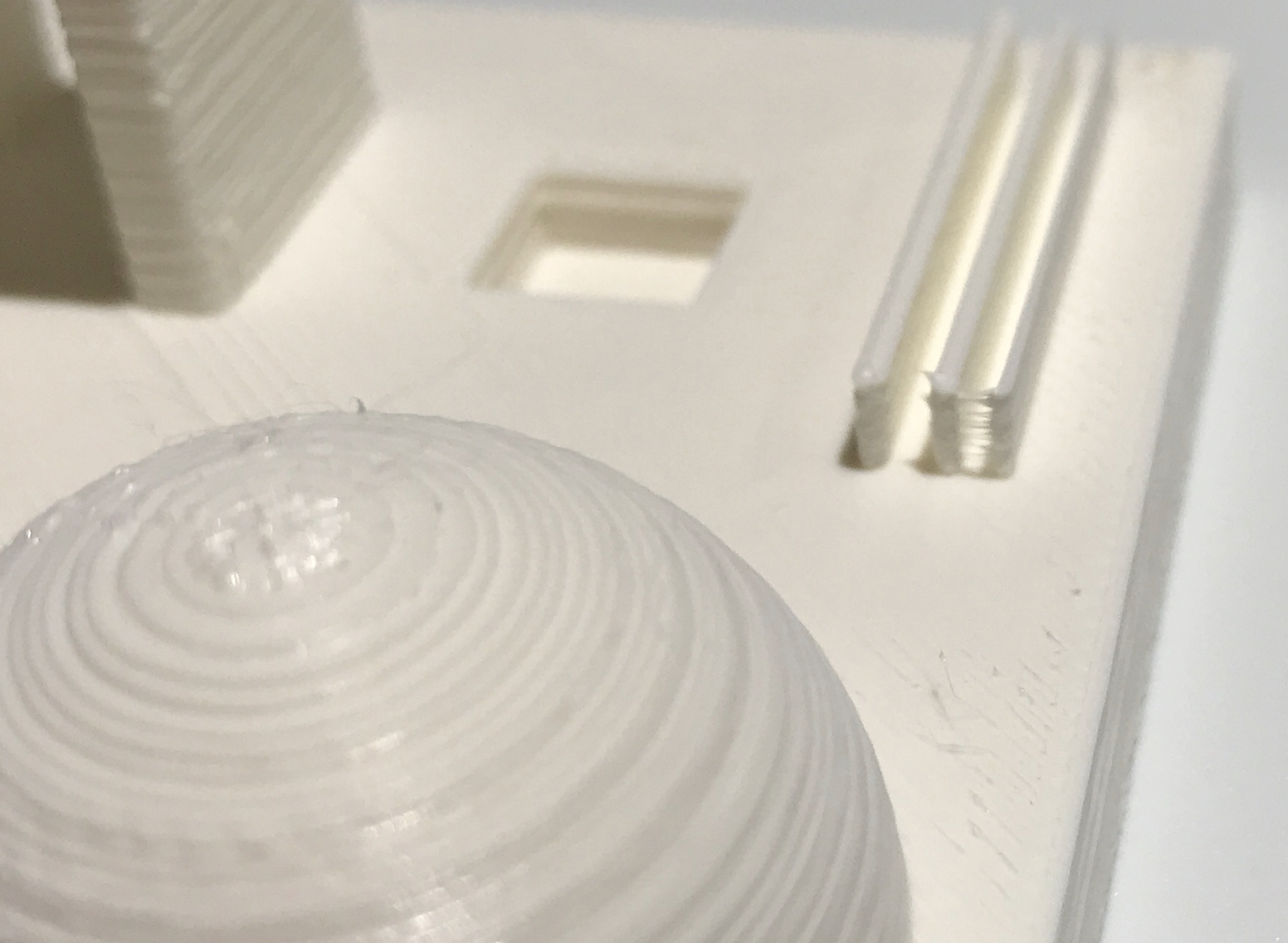

The layer height(this one is 0.4mm?) decides the product's apperance.We can see that a 0.4mm layer height is too inexactitude to print a delicate model.This half sphere is a bit rough.

Here comes an important detail.Enlarging the picture, we can see filaments connect the walls are annoying.We had batter pay more attention to the bridge distance and test a model first to adjust some arrangements.

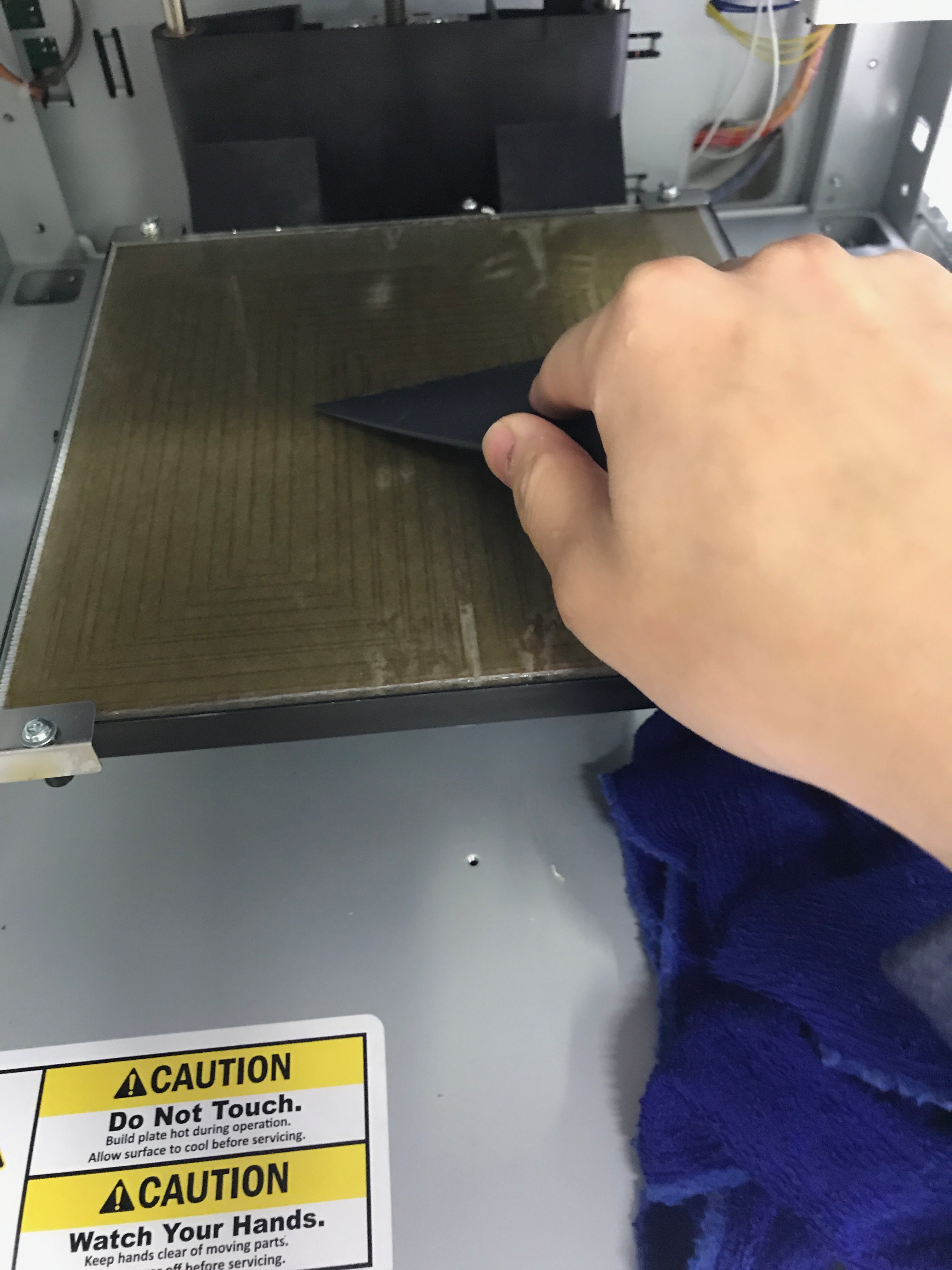

Before printing the products, we shall clean the workfloor and then put some solid glue on it.

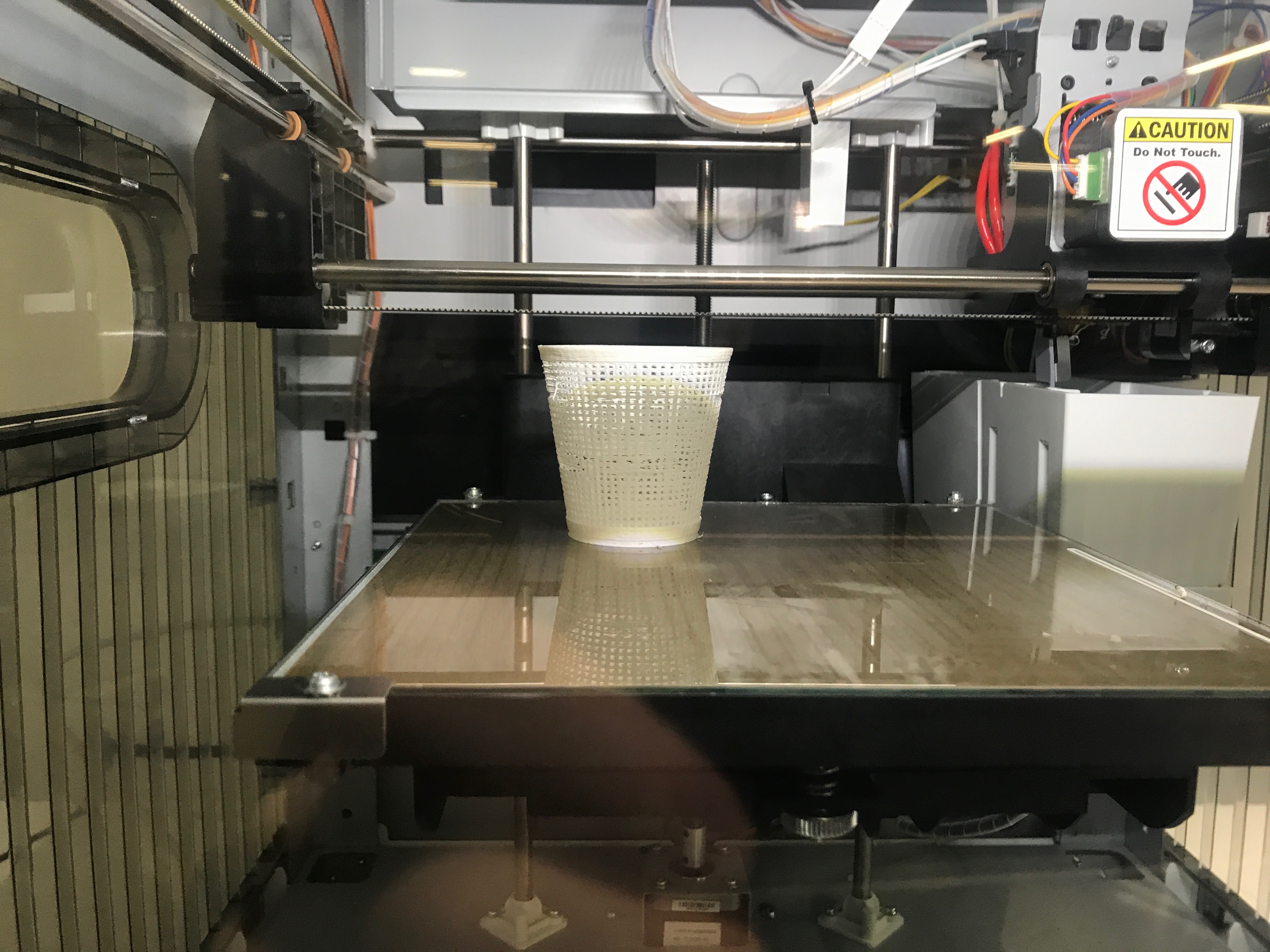

i tested a rough model with the layer height was 0.4mm and the wall is thin .

it only took 30minutes to print it out ,which gave a surprise.

Unfortunately,it was a 'surprise'!the product had already broken by its gravity when i made it out.So the first test was a failure.

the second test was a failure too ,i paused down the printer when i saw this(ps:some settings:0.1mm ,thin wall).from the two tests,i think the de vinici1.0 printer can't print my model perfectly.

i delete the other parts of my bin.

here comes my design of the bin. xyz app seems complete the model with more lines.